Industry

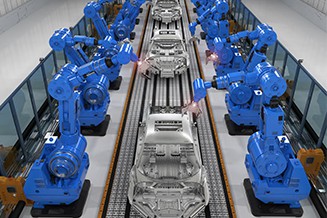

OEMs and suppliers alike rely on MOTOMAN robots in all phases of the production process. We have components and systems specifically developed for every type of Automotive application.

OEMs and suppliers alike rely on MOTOMAN robots in all phases of the production process. We have components and systems specifically developed for every type of Automotive application.

Lift, Elevators and Escalators

YASKAWA has an impressive customer base and a wealth of experience in the field of lift applications. Countless systems move using core components produced by YASKAWA.

User friendliness is the emphasis of Yaskawa drives. The keypad interface and programming are dedicated to elevator and escalator applications. The performance features are well-suited for both Induction and Permanent Magnet motors with the latest control functions.

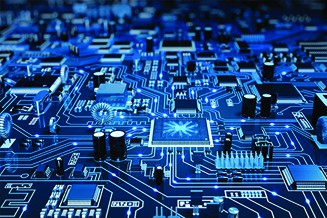

Electrics / Electronics

The advantages of our products particularly come to light when small parts and high throughput are critical to production. YASKAWA is known for high precision and provides a wide range of compact, high-speed robots that are perfect for use in the electronics industry.

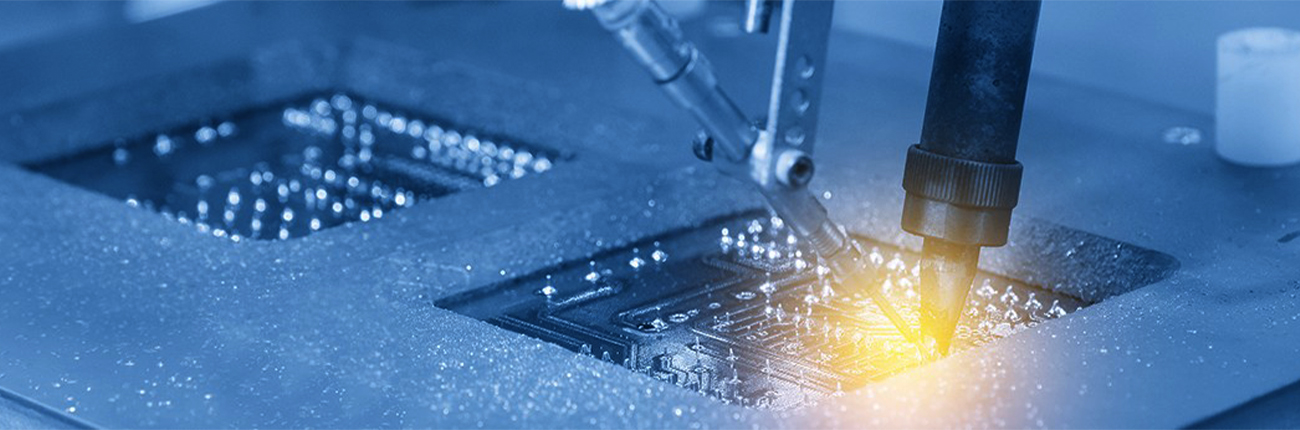

Iron & Steel

The machining of metals presents a multitude of challenges for automation:

precision and high throughput with durable, low maintenance technology. With best-in-class products and an open and ready-to-connect architecture, YASKAWA creates important prerequisites for excellent and energy-efficient solutions.

FOOD PROCESSING & PACKAGING

Yaskawa offers intelligent solutions in all types of food and beverage applications. Our experienced engineers provide proactive response and reactive troubleshooting.

Yaskawa offers packaging robot models compatible with simple-to-integrate controllers, robust vision and powerful software products. We provide the flexibility and reliability organizations need to compete.

Yaskawa also offers AC Drives and Servo Systems that available for the many specialty machines used to process and package food and beverage products. Yaskawa’s reputation for quality, performance and reliability is the foundation of our installed base of products in this industry.

Applications include :

- Compressor

- Conveyors

- Decanter Centrifuges

- Extruders

- Labelers

- Linear Flying Shears

- Mixers

- Pumps

- Rotary Placers

- Screw Feeders

- Vibration Feeders

Applications include :

- Compressor

- Conveyors

- Decanter Centrifuges

- Extruders

- Labelers

- Linear Flying Shears

- Mixers

- Pumps

- Rotary Placers

- Screw Feeders

- Vibration Feeders

PULP & PAPER

Pulp and paper facilities require specials functions and controls specific to each parts of production lines. Electric control is required to integrate those functions and controls and maximize equipment’s performance. Yaskawa offers wide range of solutions based on the many years of expertise from cutting-edge system to drive systems utilizing general purpose products, systems to enable long-term stable production with quick recovery and reduced maintenance and after-service that will ensure comfortable utilization.

HVAC AND BUILDING AUTOMATION

Yaskawa is the largest global variable frequency drives manufacturer with over 30 years of Building Automation System (BAS) and HVAC experience. Our variable frequency drives are designed for HVAC applications, which include air handlers, cooling towers, and pumps, by combining reduced size and cost with advances in performance and quality. Because every variable frequency drive (VFD) is rigorously tested, Yaskawa ensures that quality and reliability are designed and built in.

Benefit :

- Industry experience with exceptional design.

- Reduce energy use and improve system efficiency.

- Easy to install and simple maintenance.

- Easy to commission.

- Precise motor control will result in less mechanical and electrical stress on the system.

- Reductions of excess capacities at peak periods.

- Reduction or elimination of demand charges.

- Improvement in power factor.

- Total control and monitoring via the facility’s preferred communication protocol.

- Soft Starting eliminates stress on equipment that historically was started or connected across the line, including fan belts, compressors and pumps.

- Trimming the impellers on pumps may be eliminated. Water hammering will be eliminated.

RUBBER & TIRE

For rubber & tires production facilities, Yaskawa provides system solutions realizing the demands for each process, such as mixing, extruding, cutting and casting.

We provide not only systems for calendar and conveyor, but also single-drive solutions for banbury mixer, tread extruder, servo drives for casting.

In addition, we propose optimal solutions with a wide range of products complying with various overseas standards as a reliable partner for customers advancing into overseas markets.

TEXTILES

OEMs and suppliers alike rely on MOTOMAN robots in all phases of the production process. We have components and systems specifically developed for every type of Automotive application.