Painting Package

YASKAWA offers a diverse lineup of painting system packages to meet your specific needs. This lineup ranges from the MOTOFEEDER package optimized for painting small work pieces to painting systems for the inner and outer panels of automobiles and extra-large work pieces such as train carriages and construction equipment. We can propose a painting system package optimized for your work piece size, installation space, and other specific requirements.

Target Customer

Automotive Plastic Parts

We provide an industry-tailored automation process. YASKAWA offers Painting and a variety of automated solutions for small automotive plastic parts such as bumpers, garnish and back mirrors. Have experienced the automation of plastic parts processes to production automation solutions.

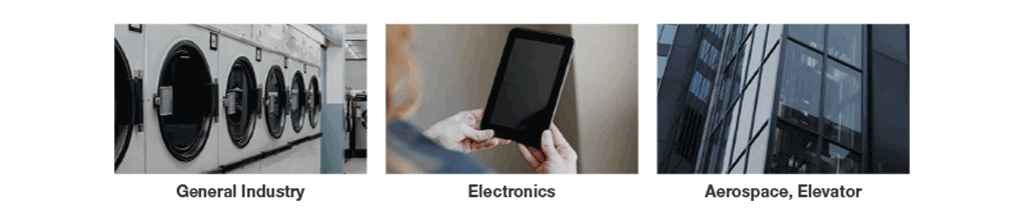

General Industries

We provide an industry-tailored automation process. From small electronic devices to large appliances, the painting system is applied to enhance the aesthetic and quality of the product. Have experience quality improvement by offering customized solutions with YASKAWA.

Standard Equipment

Painting Robot

New Type Compact Robot Optimized for Painting MOTOMAN-MPX1150/MPX1400/MPX1950 and the feedback signal for production management.

More Detail : Motoman MPX Series

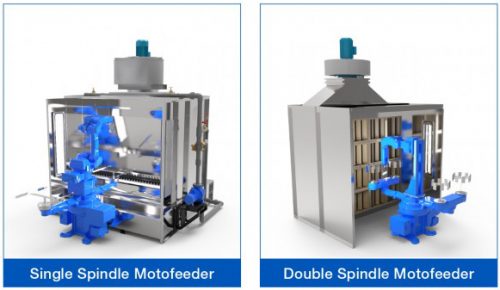

Rotational Workpiece Feeder for Painting MOTOFEEDER (Single and Double spindle)

This workpiece feeder enables you to handle a workpiece while another workpiece is painted by a robot, and helps optimization of cycle time.

This product can be used with all the painting robots for DX200 controller.

More Detail : Click Here

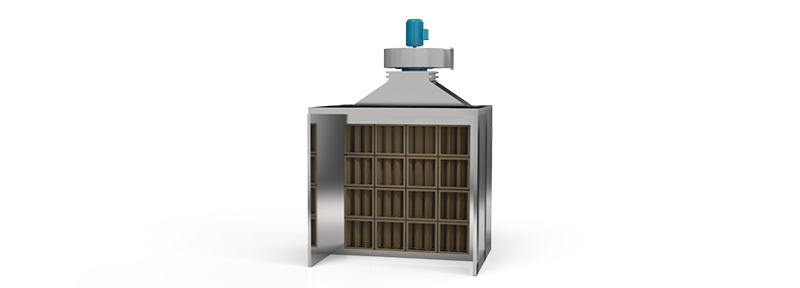

DF Series

A DF series spray booth has no washing chamber. Instead, the fan draws overspray into a filter box at the back of the booth. This traps the paint and allows clean air to be exhausted. The disposable filter box use principle of inertia separation. The overspray suffers several radical changes in direction. The paint particles, heavier than air, are projected out of the air stram.

More Detail : Click Here

VT Series

The VT series spray booth uses the unique, patented venturi plate to provide continual mixing throughout the tank. A fan create a high velocity air stream across venturi throat. This causes the surface to shear and liquid is entrained by the air.

More Detail : Click Here

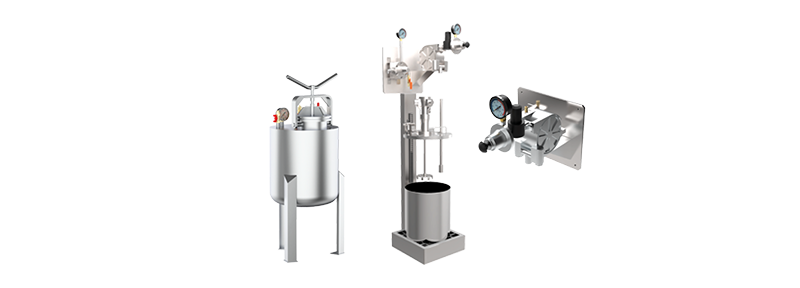

Paint Circulation System (PCS)

Every customer has different requirements on the way of feeding a paint to their applicator. ThaiPollutech has developed a standard set of PCS (Paint Circulation System) to meet customer’s need. Our model ranges from small paint usage and frequent change color.

More Detail : Click Here

Standard Gun Control Unit

Standard Gun control unit is made to control spray gun parameters. Varieties of an option are available to be chosen to suit users’ requirements. Paint parameters can be adjusted both manually and automatically. A user can track production data with our software.

More Detail : Click Here

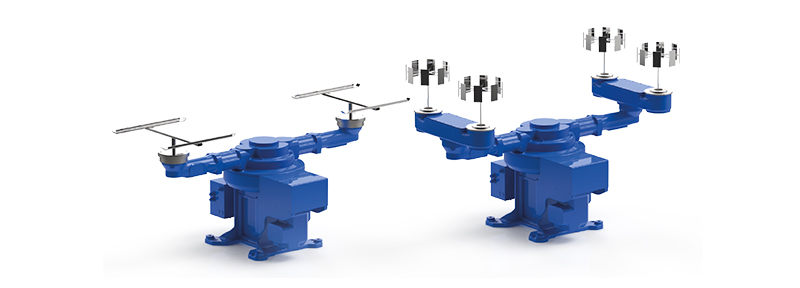

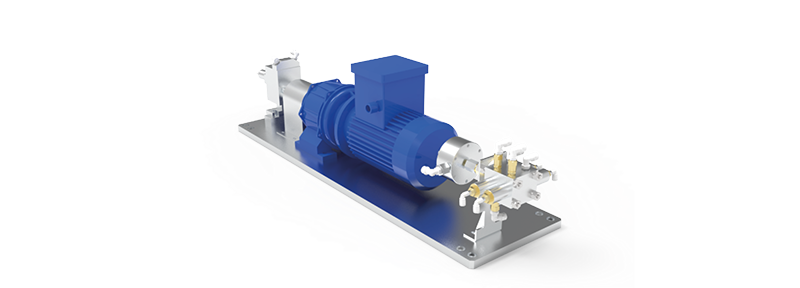

Precision Gear Pump

A gear pump provides accurate paint dosing. Our precision gear pumps are available in 0.6 cc/rev, 1.2 cc/rev or 3.0 cc/rev models. A bypass function comes as a standard function for fast flushing and loading of paint.

More Detail : Click Here

Package

*Pointer your mouse to the image to see description

Basic Package

..Target Customer..

– Already have a spray booth

– To replace manual sprayer

– Low-cost investment

Standard Package

..Target Customer..

– Don’t have spray booth or want to replace the old one with a robotic

– Completed with dynamic air chamber to fresh air supply

Premium Package

..Target Customer..

– Request full automation. completed with a painting robot and a handling robot

– Handing robot to be integrated with a loading conveyor and a baking oven